Thursday, 15 November 2012

DESIGN FOR PRINT// Print Book Process Icons

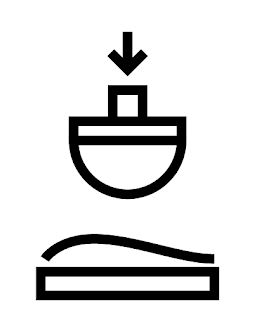

I have re-designed the icons and diagrams explaining the various printing processes to the reader. Both Digital and 'Manual' methods are explained.

Here I explain inkjet and lazer printing. I have chosen to use the same shape for the paper every time, this way the reader can distinguish between the paper and the printing bed for example.

Most digital printing is either carried out on an inkjet or laser printer. Although the quality is sub-par to other forms of printing, digital print offers instant printing, perfect for short runs and special one off print jobs. Digital printing can also be used to plan for more time consuming print methods. Ink jet printing involves multiple nozzles firing CMYK inks at a page. Laser printing is achieved by charging electrons on a toner plate, which are then transferred to paper.

I have also began using arrows to inform the reader of the direction various components in the diagrams are spinning to add further clarity to the described processes.

Offset Lithography is one of the most common ways of creating printed matter. It is seen in Newspapers, Magazines and Books, mainly because its relatively high quality and low cost make it perfect for high volume printing. Lithography can achieve this because of the use of multiple rollers to deliver the ink to the paper, keeping the impression separate from the ink, with every new rotation a fresh relief is created and transferred to the paper.

Here I add a plate above the paper icon, this is where the importance of the paper shape is noticed.

Letterpress is relief printing. It involves moving lockable type (or an image) into a bed, covering it in ink and then pressing it onto paper or any other flat surface to form an impression. Its was the first form of mass printing, developed by Gutenburg in the mid-15th century.

Flexographic printing is essentially exactly the same, however the solid block of type is replaced with a silicone relief, increasing the printable media.

Rotogravure, or Gravure for short, is a type of intaglio printing process. The print is engraved onto a cylinder, which is dipped into ink as its rotates and prints directly to the page which is guided with the help of an impression roll. Newspapers were printed with this method for a long time, today magazines, postcards and corrugated cardboard for packaging is often sent through this process. Hundreds of thousands of copies are needed to make gravure profitable.

Pad printing enables a 2D image to be printed directly onto a 3D object, for example a keyboard, beer bottle, can of coke, etc. This is achieved using silicone plates to transfer the image. Silicone is expensive, durable and most importantly can bend around 3D objects. This is pressed in ink which is then transferred to the 3D object with the pad.

Screen Printing is a print process which involves burning a pattern into emulsion which sits on a screen of tightly woven mesh. Areas which no longer contain emulsion can now allow ink to pass through the mesh screen. A squeegee is used to wipe ink across the mesh screen, the ink travels through the mesh and the pattern is transferred onto the paper beneath. Screen printing allows you to print on nearly any flat surface, however it only has the capacity for a limited run.

As the name suggests Die Cutting is the action of cutting a material like paper or leather with a die. The die itself will be made out of a sharpened metal, formed into the shape which you desire to be cut. Die cutting is used to cut out box nets and stickers, for example, and can be part of mass production.

Foil stamping and spot varnishing are typically commercial print processes. It is the application of pigment or metallic foil, often gold, silver or clear to paper where a heated die is stamped onto the foil. This makes it adhere to the surface leaving the design of the die on the paper. Foil stamping or laminating can be combined with embossing to create a more striking 3D image.

So from this hopefully you have gathered that the print book will now feature more simplistic design and iconography with more in depth explanation accompanying it. What I hope to achieve form this is to develop a resource that can be quickly picked up and glanced at for a reminder or read in full for a total update.

Labels:

Design For Print,

OUGD 504,

Print Book

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment